Understanding Melamine: Properties, Applications, and Industrial Relevance

Introduction

Melamine is an organic compound with the formula C₃H₆N₆, widely recognized for its role in manufacturing durable thermosetting plastics and resins. Known for its nitrogen-rich structure and heat resistance, melamine is a core ingredient in melamine-formaldehyde resins, which are extensively used in kitchenware, laminates, adhesives, coatings, and flame-retardant applications. Beyond its utility in plastic production, melamine has diversified into sectors like construction, agriculture, and paints due to its chemical stability and multifunctionality.

This article explores melamine’s structure, physical and chemical properties, processing characteristics, and its broad array of industrial applications.

Chemical Structure and Composition

Melamine is a triazine compound, featuring three amino groups attached to a heterocyclic ring structure made up of carbon and nitrogen. This high nitrogen content—approximately 66% by molecular weight—makes it especially useful in flame retardant formulations.

Chemical Formula: C₃H₆N₆

Molecular Weight: 126.12 g/mol

CAS Number: 108-78-1

Melamine’s stability and reactivity stem from its ability to form strong hydrogen bonds, especially when reacting with formaldehyde to form cross-linked polymer networks.

Technical and Physical Characteristics

| Property |

Value/Description |

| Appearance |

White crystalline powder |

| Odor |

Odorless |

| Melting Point |

Decomposes above 345°C |

| Solubility in Water |

Slightly soluble (3.1 g/L at 20°C) |

| Density |

1.573 g/cm³ |

| Nitrogen Content |

~66% |

| Flash Point |

Non-flammable |

| Shelf Life |

2 years in dry, sealed condition |

Melamine’s high thermal resistance and chemical inertness make it ideal for use in high-stress, high-temperature environments.

Manufacturing Process

Melamine is typically produced industrially from urea in a high-pressure process that involves:

-

Decomposition of Urea: Urea is heated under pressure, decomposing into cyanuric acid and ammonia.

-

Cyclization Reaction: Cyanuric acid undergoes trimerization to form melamine.

-

Purification: Crude melamine is purified through crystallization and washing.

Modern manufacturing techniques aim to reduce by-product formation and energy consumption while maximizing product yield and purity.

Key Industrial Applications

1. Melamine Formaldehyde Resin (MF Resin)

This is the most significant use of melamine. It reacts with formaldehyde to form durable thermosetting plastics that are:

Applications include:

-

Laminated countertops and furniture (e.g., Formica®)

-

Dinnerware and kitchen utensils

-

Electrical insulation materials

2. Surface Coatings and Decorative Laminates

Melamine is widely used in high-pressure laminates (HPL) for:

These laminates resist scratches, stains, and heat—making them ideal for heavy-use environments.

3. Adhesives and Woodworking

Melamine-based resins are popular in:

They provide excellent bonding strength and resistance to water and microbial degradation.

4. Flame Retardants

Due to its high nitrogen content, melamine is used in intumescent fire-retardant formulations. It helps suppress smoke and delay combustion, making it suitable for:

-

Coatings in construction materials

-

Flame-resistant textiles and plastics

-

Electrical equipment housing

5. Paints and Coatings

In the paint industry, melamine-modified alkyds and acrylics are used to improve:

-

Gloss

-

Hardness

-

Chemical resistance

-

Weather durability

These are ideal for automotive coatings and appliance finishes.

6. Fertilizer Additives and Slow-Release Nitrogen

Although melamine itself is not a fertilizer, its derivatives are used in:

Melamine compounds help reduce nitrogen leaching into the environment, promoting sustainable agriculture.

Types and Grades of Melamine

| Grade/Type |

Description |

Applications |

| Industrial Grade |

High purity, resin grade |

MF resins, laminates, adhesives |

| Flame Retardant Grade |

Modified for low-flame and smoke use |

Insulation, plastics, coatings |

| Technical Grade |

General-purpose grade |

Paints, sealants, fertilizers |

| Food Contact Grade |

High-purity, low-formaldehyde emission |

Kitchenware, tableware |

Each grade meets specific regulatory standards such as ISO, REACH, or FDA where applicable.

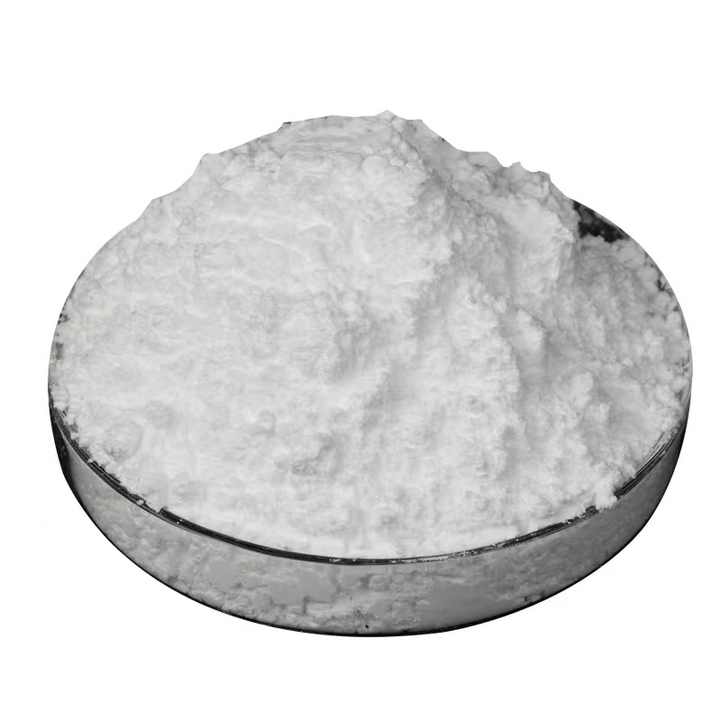

Packaging and Storage

Melamine is usually packed in:

-

25 kg woven bags with PE liners

-

500 kg or 1000 kg jumbo bags

-

Customized packaging available for bulk orders

Storage Tips:

-

Keep in a dry, cool, and well-ventilated warehouse

-

Avoid moisture or prolonged exposure to air

-

Ensure containers are sealed tightly to prevent contamination

Safety and Environmental Considerations

Melamine is considered non-flammable and low-toxicity, but certain safety and environmental guidelines should be observed:

-

Avoid inhalation of dust – use respiratory protection in industrial settings

-

Do not ingest – melamine ingestion can cause renal issues (e.g., contamination incidents in adulterated milk)

-

Proper labeling and disposal – follow local regulations for chemical handling

Regulatory Status:

Global Market and Trends

Melamine demand is driven by rapid growth in the furniture, construction, and automotive sectors. Major producers are located in China, Europe, and the Middle East. Increasing emphasis on fire safety, eco-friendly adhesives, and aesthetics continues to fuel innovation in melamine-based products.

Emerging trends include:

Conclusion

Melamine is a highly functional and cost-effective compound with widespread applications across industrial and consumer markets. Its excellent thermal stability, hardness, and compatibility with formaldehyde make it indispensable in resin production and flame retardancy. With advancements in production efficiency and sustainable formulation, melamine is poised to remain a cornerstone of multiple modern manufacturing processes.

Whether you’re engaged in resin production, construction materials, or surface coatings, understanding melamine’s properties and best practices ensures quality performance and environmental compliance.